This young material science technology startup from Jaipur is manufacturing anti-microbial face masks and other filtration methods with one of the best filtration efficiency techniques. Their secret? Graphene.

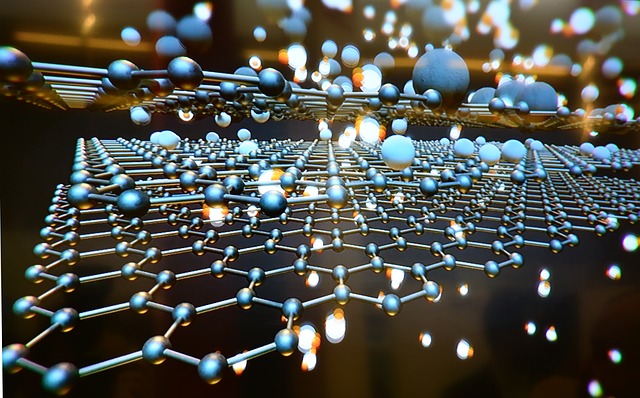

Graphene is a one-atom-thick layer of carbon atoms arranged in a hexagonal lattice. The building-block of graphite, yes, our pencil tips, graphene has several properties, because of which it has earned the title ´wonder material’.

Due to its supreme characteristics, graphene gives an extremely versatile advantage to almost every industry ranging from manufacturing aircraft to making medical sensors, from the filtration membranes for air and water to providing strong antimicrobial properties for textiles. It also gives superlative energy storage upgrades to batteries, supercapacitors, and hybrids.

One well-known property of graphene is that it is one of the strongest nanomaterials present in material science. It is only one atom thick, i.e., a thousand times thinner than human hair, and has strong antimicrobial activity. Also, it has high electron mobility and thermal conductivity at room temperature along with high flexibility.

Nanomatrix Materials is one of the first companies in the country that specializes in integration of graphene into a number of applications. Under its B2C brand G1 Wonders, the startup introduced the world´s first masks with antimicrobial NM Graphene-Silver Nanotechnology Membrane inside, which destroys the Coronavirus in seconds upon contact.

The technology has been tested with a number of viruses and bacteria at NABL certified laboratories. The masks are washable, breathable, pollution resistant, antiviral and anti-odour. The company has recently also introduced a new product range of filters for Air Conditioners using graphene-silver nanotechnology, which purifies in-room air, including sterilizing airborne microbes along with filtration of dust particles and reduced harmful Volatile Organic Compound (VOC) /gases.

The Tech Panda spoke to Vikas Bardiya, Founder of Nanomatrix Materials, about how they are using graphene to help the nation fight COVID-19.

Vikas Bardiya

There are the three key areas responsible for most transmission of infection, person to person, person to surrounding air, and person to surface. We identified this and worked on providing a solution, a material that would be able to serve the purpose, i.e., killing the pathogens at all these three levels

“There are the three key areas responsible for most transmission of infection, person to person, person to surrounding air, and person to surface. We identified this and worked on providing a solution, a material that would be able to serve the purpose, i.e., killing the pathogens at all these three levels,” he says.

Nanomatrix specializes in manufacturing graphene and its composites.

“Since graphene in itself is antimicrobial, we synthesized it in such a way that it should be reusable multiple times, washable, and be safe for use. The invention of graphene-silver nanotechnology by Nanomatrix Materials is the major breakthrough in anti-microbial coatings that can be used on any textile, filters and surfaces and these anti-microbial coating works against broad spectrum of viruses,” he explains.

The same has been tested at number of NABL certified labs.

“Not only does this technology have amazing anti-microbial properties owing to Graphene-Silver Technology, but also, the filters made using these are capable of removing PM 2.5, VOC, SOx, and NOx,” he adds.

Graphene-Silver Nanotechnology Products

The effect of Graphene-Silver Technology is effective in destroying Coronaviruses that come in contact with the membrane. When tested as per the ISO 18184 protocol, says Bardiya, Antiviral testing against the SARS-CoV-2 (the virus that causes COVID-19) virus, showed a 99% reduction and kill rate of 99% in just a matter of seconds. Therefore, this technology has been applied to serve the following three areas for COVID protection:

Person-to-Person

G1 Wonder Mask with Graphene-silver nanotechnology membrane inside were developed to stop transmission from person to person. Two types of masks have been developed:

Masks for Community

The Stylo and Eleganz range of G1 Wonders are for the common public and can be worn at public places. The wearer can enjoy the safety of having a self-sanitized graphene layer inside, minimizing transmission.

Masks for Front Liners

All N95 masks help stop the virus. However, due to direct exposure to patients, the virus particles remain on the surface of the mask, making it vulnerable to contamination for front line workers. G1 Plus N95 masks have two antiviral layers for extra protection of the wearer that stops as well as destroys/self-sanitizes the virus from the mask. Due to the tight filtration efficiency required for protection, it is recommended for front liners and doctors.

G1 Wonder Mask

Person to Surrounding Air

To prevent the transmission of pathogens from infected person through air to others in a closed room or space, G1 AC filters are developed to filter these from the air, which are supposed to be installed at indoor ACs. Since ACs work on the principal of air circulation, they are designed in a way that the entire air of the room passes through the AC.

This is where G1 AC Filters are supposed to be installed, as when the air containing pathogens pass through these filters, they trap and destroys the virus. These filters are tested as per AATCC-100 standards at the NABL certified labs. These can be installed at hospitals, clinics, public offices, and homes.

“There are some products which are providing UV based solutions to be installed in ACs. But that doesn’t work as the response time to react, trap, and destroy any pathogen is too less by UV, as there is no media of trapping the virus,” Bardiya explains.

Person to Surface

A number of studies state that the Coronavirus remains active for days on surfaces depending on the type of surface like steel, wood, paper, cloth, etc. Nanomatrix is planning to launch a range of coatings that can be sprayed on any surface creating an antimicrobial coating on the surface.

“Since graphene sheets are single layer atoms, they deposit and stick on the surface for longer time,” he says.

The major difference between a sanitizer and our spray is that a sanitizer works immediately on skin but instantly vaporises, whereas our spray remains on the object for days, meaning no daily sanitizing of these objects are required

These coatings can be coated on any surface in the room and that will make it antimicrobial for a number of days.

“The major difference between a sanitizer and our spray is that a sanitizer works immediately on skin but instantly vaporises, whereas our spray remains on the object for days, meaning no daily sanitizing of these objects are required,” he says.

Most importantly, unlike common and ordinary disinfectants, this coating doesn’t lose its activity with time because of its unique nano-architectural properties.

How Graphene Fights COVID-19

Graphene, due to its antimicrobial activity, has emerged as a saviour in this time of Coronavirus pandemic in the filtration and textile industry. Graphene technology has a unique nano chemistry that forms covalent bonds with the surface at molecular level.

“Graphene’s hydrophobicity limits the adhesion and growth of microbes on the surface of fabrics. The atomically sharp edges of graphene act as nano-knives and damage the outer wall of microbes. The presence of sp2 hybridized carbon atom in graphene structure has also given an extra edge to this anti-microbial activity,” explains Bardiya.

Graphene’s hydrophobicity restricts the adhesion and growth of microbes on the surface of fabrics. Thus, it helps in producing an antimicrobial textile, not only limiting the microorganism’s settlement on the surface but also representing a clean and dry surface

He further informs that the incorporation of graphene with textiles such as cotton, polyester, nylon in the form of coatings improves the strength of fibers and also imparts anti-static properties.

“Graphene’s hydrophobicity restricts the adhesion and growth of microbes on the surface of fabrics. Thus, it helps in producing an antimicrobial textile, not only limiting the microorganism’s settlement on the surface but also representing a clean and dry surface. Thus, it becomes an important material in medical applications,” he says.

Since graphene is a single layer of carbon atoms connected in a hexagonal pattern, it is extremely thin as well as lightweight, and therefore an attractive material for nanotechnology applications and widely used in the nanotech industry. Though at the nascent stage in the Indian context, it is attracting the attention of technologists and researchers now due to its impressive ability to store electric charge—its capacitance. This property is largely derived from graphene’s very high amount of surface area relative to its volume.

How Graphene Based Facemasks Differ from Ordinary Masks

The majority of masks that are available in the marketplace work on the principle of filtering out microbes and restricting them to enter our nose as well as mouth. However, these filtered microbes can stay on the outer exposed layer of the mask and can easily enter the body through our hands and other means. Graphene-based face masks filter the microbes and inactivate them on the mask surface when they come in contact.

“Despite their effectiveness at limiting microorganism circulation in the air, these normal masks and respirators do not completely mitigate the risk of contagion because they are susceptible to viral colonization. One of the approaches for increasing mask protection from contaminated air filtering media lies in antiviral material coatings and treatments,” Bardiya explains.

“But the existing available mask only stops the pathogens and microbes by conventional filtration method. Though some masks available in the marketplace are treated with anti-bacterial treatment on their front cloth, it does not give any filtration level, especially against the virus,” he adds.

A study evaluating the persistence of SARS-CoV-2 (the virus that causes COVID-19) on N95 surfaces showed that the virus is able to survive for up to 72-hours. In many cases, a mask wearing person was infected with COVID-19 just because they touched the outer layer of their mask.

“This problem is common with every N95 because it only stops the pathogen but does not kill it. We identified this deep-rooted problem and came up with revolutionary novel antiviral and anti-bacterial NM Graphene-Silver technology,” he says proudly.

The NM Graphene-Silver technology can be used as the outer and middle layer of any mask to make it antiviral and antibacterial. The same has also been treated on a non-woven fabric, called a graphene membrane.

“This has been used in our range of fashion masks which are for the general public and in N95 respirators that can be used by doctors and frontline workers, giving extra and longer protection to the wearer as it consists of a self-sanitizing membrane,” he says.

Our AC filters, which are fitted with our graphene membrane, destroy airborne viruses in the room. This turns your AC into an air purifier

Graphene acts as a strong antimicrobial agent for all microorganisms, and with their patented graphene-silver nanotechnology, it enhances the speed of activity tremendously.

“We have a breakthrough in the domain of air filtration domain, providing another solution to reduce the airborne circulation of germs in the room. Our AC filters, which are fitted with our graphene membrane, destroy airborne viruses in the room. This turns your AC into an air purifier. Graphene also reduces volatile organic compounds, which are secreted from furniture and paints on the wall, which no other air purifiers can do,” he adds.

Nanomatrix claims that the response time of NM Graphene-Silver Membrane against SARS CoV-2 is less than 15 seconds (99% kill rate in 15 seconds) based on test results of NABL certified Lab. These properties of NM Graphene Silver technology make it revolutionary.

Is a Graphene Mask Safe?

There are some concerns related to graphene masks, such as recent findings by Health Canada, that they can cause health problems. They suggest that graphene can be harmful to human health if inhaled while using graphene-based masks. Are the masks produced by Nanomatrix safe?

Bardiya replies that as per Health Canada’s statement, they have conducted the preliminary study on a small portion of market available graphene products.

“As we all know, every material has a safe use limit, say with vitamins, minerals, hormones, food, water and even oxygen. The same principle applies to every material with which the human body is being exposed. Graphene and other nanomaterials also follow the same phenomenon,” he explains.

The toxicity of graphene depends on various aspects of its uses in the products and its intrinsic properties. Before understanding the toxicity of graphene, it´s important to learn about the graphene family.

The graphene family of materials mainly include single layer graphene (SLG), double layer graphene (DLG), graphene quantum dots (GQD), graphene nano platelets (GNP), graphene oxide (GO) and reduced graphene oxide (rGO), etc.

“All these materials have completely different chemical/physical structure and different properties like surface area, number of layers, lateral dimension, surface chemistry, functionality and purity, etc. All of these properties play a big role in the toxicity and biocompatibility of any material. The properties also change their values with changes in the manufacturing methods of the graphene,” he says.

There are two major synthesis methods being used by the industry and research community.

Top-Down Synthesis Approach

The top-down approach exfoliates or separates graphite (or any graphite derivatives) to form graphene and its derivatives. The same proprietary method is being used to make NM Graphene and its derivatives, which uses high quality natural graphite as its precursor. This method can control graphene’s functionalization, lateral size, number of layers, surface chemistry and purity.

Bottom-Up Approach

On the other hand, bottom-up approaches include the growth of small molecular carbon precursors to form graphene, commonly known as biomass graphene. Here, the precursor can be any bio-based product or agriculture waste. The control of material properties during manufacturing is difficult in this method, has limited functionality, and is subject to leaching. Leaching is a loss or extraction of certain materials from a carrier into a liquid (usually, but not always a solvent).

Both of these methods produce different qualities of graphene with different properties. Masks produced using biomass graphene have concerns of leaching.

The toxicity aspect of graphene/nanomaterials-based products, also depends on how the materials are being used in the product, the amount of material used, and whether the material is leaching or not.

“In nanotechnology, high amounts of nanomaterial doesn’t result in better properties, similarly in this case, higher amount of graphene in the mask doesn’t mean higher antimicrobial properties. Excess amounts of material may cause loss of properties and higher leaching,” Bardiya says.

Most of the available graphene masks in market are using only graphene that too in excessive quantity. Only graphene, without proper functionalization also leads to poor binding with the textile fibres in the mask.

“Nanomatrix’s in-house R&D and rigorous test works has resulted in NM GTx, a Graphene-Silver nanocomposite based antimicrobial textile treatment. It is safe for human use. The same has been tested on graphene membrane at third party laboratories for leaching and it was found that there was no leaching of graphene particles,” he adds.

How Graphene Enhances Anti-Bacterial Properties of Clothes

Graphene is widely used to make technical textile, using graphene composite at the fiber stage or yarn stage or even at the fabric stage. This technology can be used on both natural fibers and synthetic too.

“After rigorous R&D, graphene’s unique synthesis formula with silver nanomaterials was invented and it showed strong antiviral and antibacterial activity. The atomically sharp edges of graphene act as nano-knives that have the ability to damage the outer wall of microbes,” Bardiya explains.

Graphene has been rightly called the “wonder material” of the 21st century, especially for nanotechnology applications. The applications of graphene have no bounds

On the other hand, silver nanoparticles produce reactive oxygen species (ROS) in oxidative conditions; can attack external enzymes and proteins leading to irreversible damages to the genetic material of viruses and bacteria. Thus, Graphene is widely used in the textile industry, especially for surgical-based textiles.

“Graphene has been rightly called the “wonder material” of the 21st century, especially for nanotechnology applications. The applications of graphene have no bounds. This wide-ranging application of graphene in every field is due to the outstanding properties of the graphene sheet,” he says passionately.

How Nanotechnology Enhances the Properties of Graphene

Nanomatrix Materials has developed a number of advanced nanomaterial solutions across sectors, which include textile, marine, electronics, mechanical, etc. Their NMG–Tx, a patented Graphene-Silver Technology, is strongly antiviral and anti-bacterial. The membrane developed by using nanocomposite is quite effective in face masks, including non-surgical face masks and N95 face masks.

“The majority of non-surgical face masks available in the marketplace can only stop the virus from coming in contact with you, but using NM Membranes in the non-surgical face mask as one of the layers can not only stop the virus but also destroy it instantly,” Bardiya says.

“The applications of this membrane are infinite; it can also be used in air filtration also to kill the virus present in the surroundings” he adds.

The nanocomposite can also be applied to any kind of textile, making the entire attire anti-microbial. They are also planning to use this technology in the HVAC system, designing filter media for hospitals, malls, airports, and other mass gathering places.

Graphene Based Nanotechnology Use

The applications of graphene have no bounds ranging from electronics to filtration, energy to construction, and coating to sensors. These wide-ranging applications of graphene in every field are because of the outstanding characteristics of the graphene sheet.

“Today, microbial infections represent the major reason for healthcare-associated infections (HAIs), hospital-acquired infections, and biomaterials implant failure. However, most hospital surfaces and available implantable materials do not hold antimicrobial properties, thus requiring antibiotic therapy once the infection occurs,” Bardiya says.

Graphene and related materials demonstrate a wide range of antimicrobial activity against bacteria, fungi, and viruses. These antimicrobial activities are attributed mainly to the direct physicochemical interaction between germs and microbes, which makes it more effective than any other conventional surface disinfectant.

Read more: Khelega India? Indian GenZ aren’t that serious about going pro in eSports survey reveals

“The major application area for graphene is the removal of microbes from the air and the surrounding environment by using nanotechnology in air filtration. This property has proven its practicality in the current pandemic situation also,” he concludes.

Graphene can also be used as a universal antimicrobial coating on any surface in public places, hospitals, malls, restaurants, etc. Nanomatrix Materials is solely working on the large-scale manufacturing of graphene and its derivatives and finding amazing applications for them in the field of filtration, energy, construction, coatings, and much more.